(706) 395-6239

Services

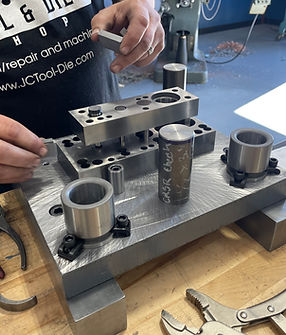

JC Tool & Die brings exceptional craftsmanship and innovation to designing, proto-typing, and building metal stamping dies. Our shop is designed and outfitted to provide high quality dies and replacement die components. We specialize in micro to medium size die builds. We are well-versed in designing a wide range of dies including progressive, draw, form, single hit, transfer, and proto-type dies.

We added production machining capability in 2022 when we purchased our CNC vertical mill and wire edm. JC Tool is able to take on short and long production runs with the same quality and precision we offer in our die designs & builds.

In 2023, we continued to grow and was able to offer stamping services for short or long production runs. Our 75 ton press is capable of stamping a wide variety of material up .1875 thick material.

Our L & J 60 Ton punch press was added in 2025. This press expands our capacity to take more stampings. We are looking to add additional punch presses in the coming year.

JC Tool & Die also offers engineering services from die design to reverse engineering. We will provide you with both 2D and 3D part drawings / assemblies.

We are ITAR registered, woman-owned business working towards ISO 9001 certification. We take pride in our quality. Through continuous process improvements we strive to meet or exceed our customers' needs.

Equipment

-

Acer lathe, 14" swing, 40" gap with Digital Read Out

-

Bridgeport Mill, 9" x 48", power feed, DRO

-

Clausing Mill, 9" x 48", power feed, DRO

-

Haas CNC Vertical Mill, 20" x 16" 20"

-

Sodick Wire EDM, 7.5" x 9.5" x 13.5"

-

Medina End Grinder, 10" x 15" chuck, 46" wheel height

-

Mitsui Precision Form Grinder, 6" x 12"

-

Okamoto Surface Grinder, 6" x 18"

-

Okamoto Wet Grinder, 16" x 32"

-

Bliss C75 Ton Punch Press, 14.5" shut height, 24" x 36" bolster

-

L & J W60 Ton Punch Press, 15" max shut height, 24" x 38" bolster

-

BadBoy Sandblast Cabinet, 20" x 20" x 43"

-

Cress Heat Treat Oven, 6" x 6" x 9"

-

Cress Heat Treat Oven, 10" x 12" x 20"

-

Wilson Rockwell Tester, 16" height capacity

-

Nikon Toolmaker Microscope, Quadracheck digital readout

-

Gage Master Finite 20 Horizontal Comparator